21 November 2017

|

|

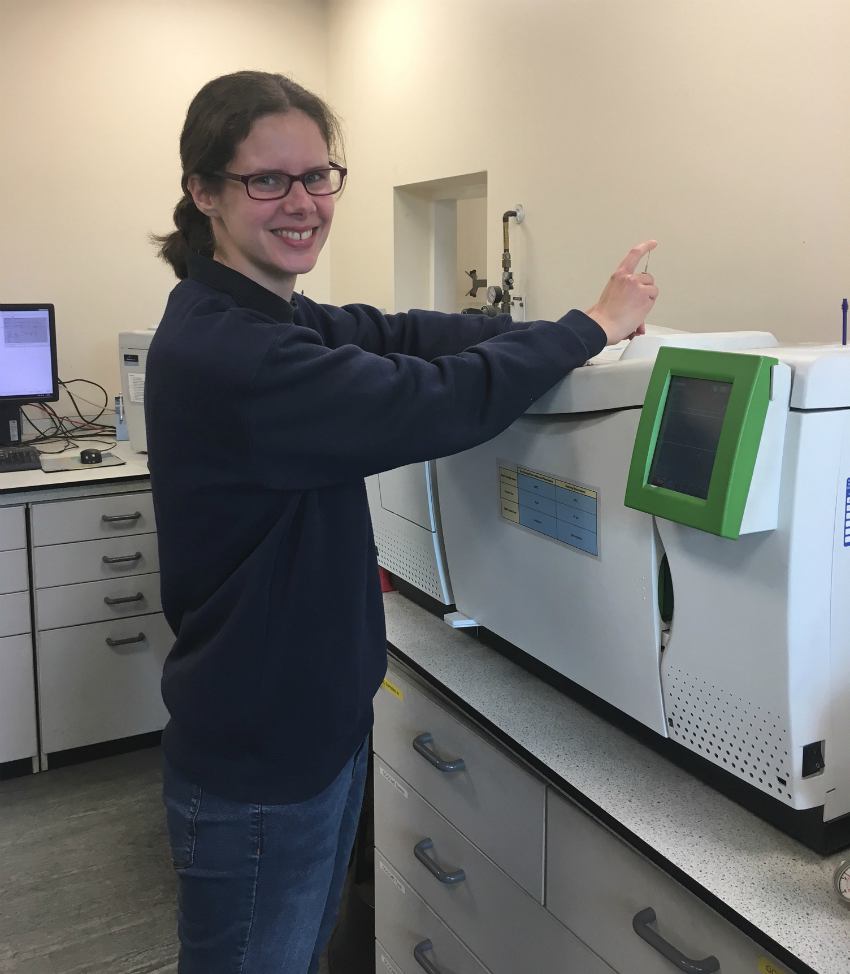

In the latest in our Women in ACR series, we meet Christine Gaskell, quality and process analyst at A-Gas UK.

What does your job involve on a daily basis? In the A-Gas laboratory at Portbury near Bristol I carry out routine analysis of the waste refrigerants that we receive from customers and quality control checks on the gases that we supply them. A significant part of our business is collecting and processing recovered refrigerants. This involves removing contaminants and then returning the clean gases to the market. |

These recovered refrigerants play a key role in the supply chain as the F-Gas restrictions on the production of virgin refrigerants begin to have an impact on the market. A-Gas has invested heavily in new equipment to recover refrigerants as it has recognised that this area of the refrigeration industry will grow in the coming years.

We test for purity, composition and moisture, and carry out residue analysis and monitor acidity levels. We carry out these checks to ensure that what we are selling is exactly what is being received by the customers and that they have confidence that what they are buying is going to do the job properly.

I am also involved in method development work on behalf of A-Gas. Here I look at how to improve laboratory processes and investigate alternative ways of carrying them out. I examine how the instruments work and perform, and see how we can improve the efficiency of them.

What is your background?

I am a chemist and while at university undertook research into catalysis. This is used traditionally to increase the rate at which a chemical reaction takes place or open the possibility of a new reaction pathway that wouldn’t normally occur. I investigated metal and metal oxide catalysts and studied how the reaction proceeded on the surface. The outcome I was looking for was a product with greater purity and less contaminant. This is an important and interesting area of green chemistry.

How did you join the refrigeration industry?

I am 31. I graduated in 2008 and then completed a PhD at Cardiff University in catalysis and finished my post-graduate work in this field in 2012. I then moved to Bristol with my husband and was looking for a chemistry-related job. I saw this position with A-Gas advertised and thought this maybe was the one for me.

What makes it the job for you?

The first thing that attracted me to the role was the instruments and the techniques used. I didn’t really know that much about refrigerants when I began working for A-Gas but the analysis techniques, and particularly one instrument, involving spectrometry is something I had been familiar with. This can fingerprint molecules based on their mass by firing a high energy stream at the particles. I like working with equipment in the laboratory, and finding out what happens in processes, and through this work my knowledge of refrigerants has widened.

Why are there so few women working in the industry?

I suspect it may be due to a lack awareness of the opportunities that lie in the refrigeration and air conditioning industry. The manual side of the industry does put off some women and it could be that for them it is a job that lacks the necessary glamour. I think it all boils down to the fact that many women don’t know about the opportunities that are available and the great careers that are on offer.

A traditional route into the industry is through the technical engineering roles but these tend to be male dominated and maybe we have to look at this aspect of recruitment in a different way.

Do you have time for a job and a family?

I am married to John and I have a son Daniel who will be two in December. In my spare time I like to garden and, when I have the opportunity, play the violin. Unfortunately, with a young son I don’t get this particular instrument out of the case very often these days. I had passed my Grade Eight music examination but unfortunately I just haven’t the time to play the violin at the moment.

What’s your next career move?

This role really suits me as I only work two days a week. I have a really good work-life balance and this allows me to look after Daniel and also have a stimulating job. When Daniel is older I will be able to consider future career moves. Having said that, I do enjoy this job because I am not stuck at a desk all day and I am working with a really good team.

www.agas.com

We test for purity, composition and moisture, and carry out residue analysis and monitor acidity levels. We carry out these checks to ensure that what we are selling is exactly what is being received by the customers and that they have confidence that what they are buying is going to do the job properly.

I am also involved in method development work on behalf of A-Gas. Here I look at how to improve laboratory processes and investigate alternative ways of carrying them out. I examine how the instruments work and perform, and see how we can improve the efficiency of them.

What is your background?

I am a chemist and while at university undertook research into catalysis. This is used traditionally to increase the rate at which a chemical reaction takes place or open the possibility of a new reaction pathway that wouldn’t normally occur. I investigated metal and metal oxide catalysts and studied how the reaction proceeded on the surface. The outcome I was looking for was a product with greater purity and less contaminant. This is an important and interesting area of green chemistry.

How did you join the refrigeration industry?

I am 31. I graduated in 2008 and then completed a PhD at Cardiff University in catalysis and finished my post-graduate work in this field in 2012. I then moved to Bristol with my husband and was looking for a chemistry-related job. I saw this position with A-Gas advertised and thought this maybe was the one for me.

What makes it the job for you?

The first thing that attracted me to the role was the instruments and the techniques used. I didn’t really know that much about refrigerants when I began working for A-Gas but the analysis techniques, and particularly one instrument, involving spectrometry is something I had been familiar with. This can fingerprint molecules based on their mass by firing a high energy stream at the particles. I like working with equipment in the laboratory, and finding out what happens in processes, and through this work my knowledge of refrigerants has widened.

Why are there so few women working in the industry?

I suspect it may be due to a lack awareness of the opportunities that lie in the refrigeration and air conditioning industry. The manual side of the industry does put off some women and it could be that for them it is a job that lacks the necessary glamour. I think it all boils down to the fact that many women don’t know about the opportunities that are available and the great careers that are on offer.

A traditional route into the industry is through the technical engineering roles but these tend to be male dominated and maybe we have to look at this aspect of recruitment in a different way.

Do you have time for a job and a family?

I am married to John and I have a son Daniel who will be two in December. In my spare time I like to garden and, when I have the opportunity, play the violin. Unfortunately, with a young son I don’t get this particular instrument out of the case very often these days. I had passed my Grade Eight music examination but unfortunately I just haven’t the time to play the violin at the moment.

What’s your next career move?

This role really suits me as I only work two days a week. I have a really good work-life balance and this allows me to look after Daniel and also have a stimulating job. When Daniel is older I will be able to consider future career moves. Having said that, I do enjoy this job because I am not stuck at a desk all day and I am working with a really good team.

www.agas.com

Content continues after advertisements