22 April 2021

|

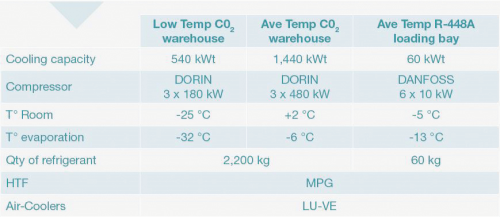

Refrigeration specialists INGENIUM has supplied a warehouse complex in the Russian port of St Petersburg with refrigeration systems for a large logistics company, a world leader in sea container transportation with over 80,000 employees across 130 countries.

Working in partnership, the customer asked INGENIUM for a technical solution specific to the design format of their warehouse. Russia is moving towards environmental standards following the adoption of the Kigali amendment, and so during the development phase, a design option put forward was to find a solution that used CO2 as a refrigerant. CO2 technology would allow for a significant reduction in future operating costs whilst also removing potential issues in terms of restrictive measures.

The solution was accepted in principle by the client but at the project planning stage, made additional requirements regarding the configuration of the warehouse. They also needed to cool the loading bay for the loading and unloading of goods. The area needed to be cooled to -5°C.

Various environmental compliance options were considered. One of them was to use the HFO Solstice N40 (R448A) for the independent refrigeration circuit serving the loading bay. The benefit of using this refrigerant is its lower global warming potential compared to R-507A, which is still largely used in Russia for similar applications. Climalife, the refrigerant supplier, provided the necessary technical support for selection.

Solution

INGENIUM offered the Optyma Plus compressor and condensing units from Danfoss. These are compact systems with a good aesthetic appearance, making it possible to place them in the area next to the loading bay doors, cooling the air in the entrance to the low-temperature chamber.

The units are designed to reduce the amount of moisture entering the chamber as they process the air entering this zone. A large percentage of the moisture that enters the bay from outside is removed during the cooling process by the evaporators in the entrance.

Testimonial

Alexander Nadeev, head of integrated projects, said: "The use of R448A for this zone was led by the need to minimise costs and the customer's requirement to comply with environmental regulations - they are looking to the future in terms of stopping using HFCs with high GWP."

The units operate independently of the main refrigeration system, starting on demand during loading and unloading in the areas being served and when the outside temperature is higher than -5°C. Defrost of the evaporators is carried out by electric elements. The correct design and application of the project have helped to significantly reduce the energy consumption of the cooling system, thus reducing operating costs and shortening the payback period of this investment project. For air coolers, it was decided to use a system for defrosting electric fuel elements.

Carrying out a full cycle of works on the production, installation and commissioning of equipment for the cooling of the warehouse complex. INGENIUM general manager, Christophore Dzhibgashvili, said: "Our priority is to be very focused on the task briefed by the customer and we find unique approaches to our solutions."