30 July 2019

|

Breakdowns can be catastrophic for cold storage warehouses, and require a fast and effective response to avoid the damaging consequences associated with rising temperatures in rooms where products are stored. Matt Watson, sales manager at Aggreko, explains how emergency cold storage units offer warehouse owners and operators a swift, reliable solution in these circumstances.

Cold stores can contain millions of pounds worth of stock at any one time and are reliant on chilling systems to keep air temperature at -22°C or below, ensuring product integrity. If these systems were to break down, any influx of ambient air into the cold store can have a major detrimental effect on this stock. Indeed, if store temperature increases by just a few degrees any stored frozen goods may need to be thrown away, at large financial cost.

Cold stores can contain millions of pounds worth of stock at any one time and are reliant on chilling systems to keep air temperature at -22°C or below, ensuring product integrity. If these systems were to break down, any influx of ambient air into the cold store can have a major detrimental effect on this stock. Indeed, if store temperature increases by just a few degrees any stored frozen goods may need to be thrown away, at large financial cost.

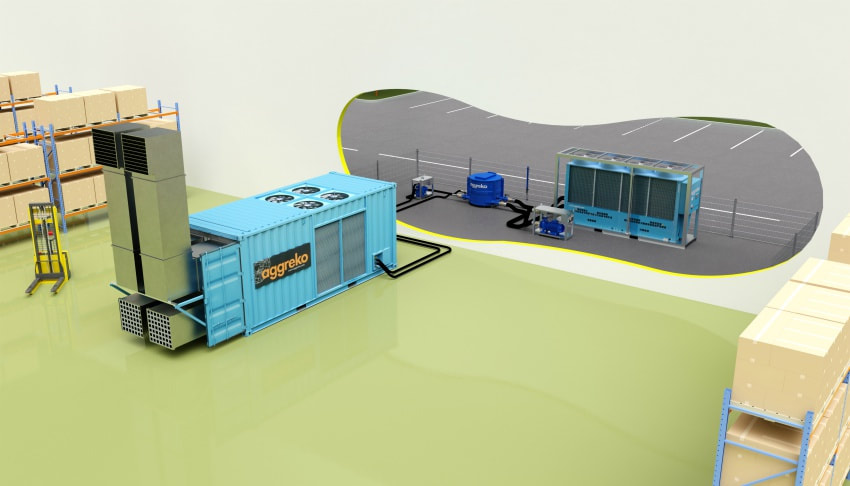

| Faced with this situation, it is standard practice for store managers to lock the store down to preserve cold store temperature for as long as possible. If locked down, the store will hold temperature for a number of days, but would have a detrimental effect on the supply chain served by the cold store. This time window is absolutely vital if the integrity of the cold store is to be maintained and its products kept in optimum storage condition. Traditional option The traditional option in these circumstances is to opt for a refrigerating solution that involves installing chillers, and hoses outside the cold store site, with several air handling units installed inside. However, installing such a solution can take two to three days, and during this time temperature within the cold store will be continually rising. Consequently, though the new installation may ensure the store keeps running with temperature restored to -22°C, clients may still have to throw products away unless they act extremely quickly once system failure occurs. Yet because breakdowns are often sudden and unexpected, it is difficult to guarantee this immediate, planned response ahead of time. As a result, warehouse owners and operators are likely to end up disposing of thousands of pounds worth of now-spoiled stock if such a situation were to occur. Emergency cold storage This risk of product spoilage can be avoided through the use of temporary air-cooled low temperature DX units. Aggreko, for example, offers a plug-and-play solution housed in a 20ft container, which is a direct expansion unit that delivers 100kW of air at -22°C, all housed within a single unit. Crucially for cold stores, solutions such as these are designed for rapid response, offering a quick and easy installation for freezing and cooling store rooms. One of the benefits of emergency cold store units is the time saved on installation. It can be deployed quickly and installed in hours once on site, returning affected storage rooms to regular chilling temperature. This means regular warehouse operations can be resumed without affected frozen or chilled goods having to be thrown away or decanted into another cold store. Furthermore, these emergency cold storage units can be used to carry out multiple processes, depending on what processes are used on site. This includes blast freezing – quickly cooling down hot products such as food to ambient temperature or below extremely quickly so they can be packed without sweat occurring inside the wrapper. These units can also be used for holding chill scenarios, in which a product is moved in its frozen state into a holding freezer, where it can be kept for prolonged periods before being supplied to the customer. Furthermore, the unit can be utilised for chilled storage operations, delivering 100kW to maintain air at 0°C, ensuring chilled foods remain at refrigeration temperatures. Unique alternative Due to its unique concept, this solution does not take up valuable space inside the affected cold or chill Store. All setting and operating can also be made from outside, and the unit can be converted into a water-cooled system if there is no space available to install it externally. By contrast, a traditional solution requires the installation of both external and internal equipment. These parts, including chillers, pumps and hoses, may take up valuable space within what can be a very tight environment. Consequently, this can lead to a more costly, lengthy and logistically complex installation at a time when speed and simplicity are a priority. Indeed, because these units can be installed much more rapidly than traditional solutions, emergency cold storage units can give owners and operators more time to consider their next step following a system breakdown. Additionally, Aggreko’s fleet of temporary power generators means that if the site us unable to provide access to mains power the additional capacity required for the unit can be supplied as part of any installation. Further functionality Temporary air-cooled low temperature DX units are not only limited to use during breakdowns and emergencies. They can also be used as a temporary cooling solution during planned shutdowns, allowing the cold store to continue operating while a fixed cooling solution is being maintained or upgraded. Beyond unplanned and planned shutdowns, these units can also offer an excellent option for companies looking to stockpile products. For example, a cold storage warehouse operator may wish to increase their capacity to store food and pharmaceutical products for periods where demand will spike, or to safeguard against uncertainties such as Brexit. Increasing storage capacity without installing further chillers and chilled air distribution systems could place added strain on existing plant infrastructure, making a breakdown more likely. By implementing a temporary solution, it would be possible to transform a regular, ambient-temperature storage space into a cold store and ensure the warehouse meets required temperatures for these busier periods. Crucially, these temporary units adhere to appropriate industry standards surrounding chilled and refrigerated products, so cold storage warehouses can increase capacity when required quickly, safely and easily. Final thoughts Companies who rely on cold storage warehouses can face two main risks – a lack of capacity during periods of peak production and high demand, and the possibility of system failure. Emergency cold storage units that are available for hire can also be delivered and installed at short notice, meaning production is not impaired and customers can avoid issues that may arise around product spoilage, and its ensuing costs. Emergency units are also ideally placed to assist companies looking to improve their chilled storage capacity temporarily, putting retailers, manufacturers and warehousing sector professionals’ minds at ease. www.aggreko.com |

Content continues after advertisements