18 April 2024

|

Steve Shipp, Managing Director of Ultra Refrigeration, explores the vital role played by efficient refrigeration equipment in keeping the cold chain moving towards Net Zero, and urges operators to act now to have any chance of meeting energy reduction targets.

The Government’s ambitious plan to combat climate change requires the UK to become Net Zero by 2050. However, it’s clear that the changes required to make this target a reality across the UK’s industries and businesses are simply not happening fast enough.

The Climate Change Committee, the independent body set up to advise the UK on emissions targets, has called for urgent action from the Government; ‘to commit to bolder delivery … when pace must be prioritised over perfection.’ The Government itself seems uncertain how to balance short-term economic pressures against long-term climate goals, while also trying to win popular support for its policies.

There are Government grants for energy efficiency advances in some sectors - the domestic Boiler Upgrade Scheme, for example, which encourages the take-up of heat pumps - but other sectors, such as the cold chain, are left to their own devices.

The challenge for cold chain operators

With no clear Net Zero vision for our industry, little direction offered via Government or legislation, and a lack of joined-up thinking (e.g. the debate about using the lowest GWP refrigerant rather than the most efficient) it’s no wonder that operators are confused about how best to achieve targets. Given that the lifecycle of large refrigerant plant may be as long as 20-30 years, it’s clear that any equipment being specified now needs to be Net Zero-ready.

Refrigeration plant will likely represent more than 60% of the total energy usage for most operators within the cold chain. This fact, combined with the high costs of energy and the quest for Net Zero, already focuses minds on increasing the efficiency of refrigeration equipment and looking at ways of sourcing sustainable energy. Many are already generating and/or storing their own energy in order to reduce costs and offset their impact on the climate.

But as an operator in the cold chain, there will always be a need to run a refrigeration system; the efficiency of this equipment will be key to reducing ongoing energy usage. At the latest Cold Chain Live! event, respected speakers urged cold chain operators ‘not to wait for the stars to align before you take action’ and to ‘try things and be prepared to fail fast and move on.’ So how, as an industry, do we go about ensuring we’re ‘energy smart’?

First steps to ensuring we’re ‘Energy Smart’

Our view is that now is the time to look closely at your existing system and decide how, or whether, it’s going to deliver the energy savings required to meet Net Zero targets.

Looking after your existing equipment

Planned service and maintenance should be in place to ensure ongoing efficiency and avoid possible failure at peak loads. Something as simple as keeping condensers clean for example; clogged fins can restrict airflow and increase energy usage by 23%. Or ensuring optimal refrigerant levels; a 15% refrigerant shortage sees a 100% increase in energy.

Look at all aspects of the operation; the integrity of the cold store itself - the insulation material, the vapour-seal joints between panels, the correct operation of doors - should be examined carefully to ensure optimum working.

Using either available data or desk-top calculations, it should be possible to create a theoretical load profile for the whole refrigeration system which can then be used to examine where energy savings can be made. If you don’t have the expertise to do this in-house, then we suggest you call in experts to do this for you.

This exercise should point towards ways in which your existing system could be made more efficient, or suggest that a new system would be a better bet.

Planned service and maintenance should be in place to ensure ongoing efficiency

Upgrading your existing system

There are usually a number of ways to improve the efficiency of existing equipment, through replacement components or via more intuitive control strategies. It could be that these changes have not been considered previously because either the data or the load profile wasn’t available, or the energy savings were considered negligible. Now however, all marginal gains need to be explored.

Alternative components might include, for example; the use of variable speed drives (VSDs) on compressors to provide variable capacity control; EC fans (which, at half-speed, use one eighth of their full power, representing an energy saving of up to 70% over ‘standard’ AC fans); electronically modulated valves; and pressure regulators.

Different control regimes could include; floating temperature setpoints on usage; use of structured shut-downs of equipment based on the load profile; and a change of defrost strategy amongst others.

Specifying a new system

The opportunity to specify a whole new refrigeration system provides the greatest chance to ensure the best outcome in terms of ROI and Net Zero targets. The design can consider the overall operational demands in detail, the system requirements, the type of refrigerant, and the available budget. The earlier the design of the refrigeration system is considered as part of the investment process, the more options are available and the greater the energy impact of the overall design can be.

Taking a holistic approach to new-build design challenges provides greater opportunity for innovative solutions. For example, looking at the overall heating and cooling demands of the whole site - and perhaps the wider community - can open the door for heat recovery systems to utilise heat elsewhere, so reducing overall energy usage.

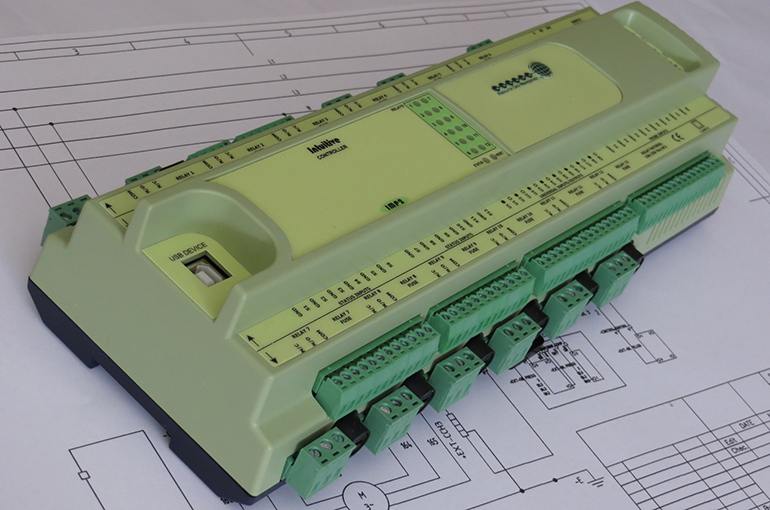

Advances in software design and flexibility mean that what can be achieved from a system in terms of data gathering, control and monitoring for energy efficiency is often only limited by your imagination. As no two businesses are identical, off-the-shelf software solutions are usually not the best fit; programming according to precise system needs is the way forward.

New generation controllers and advances in software open up opportunities for energy efficiencies

Act now to hit targets

The many technologies applicable to refrigeration - design, equipment, software - are evolving fast in terms of energy efficiency. This very speed of advancement may encourage some to delay investing, preferring to wait until efficiencies are further improved in the future. And then there’s the question of whether to upgrade your existing equipment or look to invest in a new system.

Our view is that all the time we do nothing, we leave ourselves with less time to make the difference to move towards Net Zero, and more difference to make up.

We would encourage a more immediate and radical approach; be brave, do things differently. In short, innovate, take risks, pioneer new solutions, do more trials and discover the data required to make sound decisions.

Finally, trust your supply chain to create the ideas and deliver the solutions.

Ultra Refrigeration

We consider ourselves leaders in energy efficient cooling solutions and innovative heat recovery technology. Whatever the scale of your project, contact Ultra today on +44 (0) 330 2232404 or [email protected], or visit our website at https://ultra-refrigeration.com/