08 August 2018

|

| A-Gas Quality and Compliance Manager Francis Burraston explains how problems with compliance can be avoided by getting it right first time. The Hazardous Waste Regulations have a significant influence on the way that we all handle refrigerants. They ensure that refrigerants are collected, transported, recovered and disposed of safely. In doing so we are able to better protect those who are handling refrigerants, safeguard the environment they are working in and reduce the overall environmental impact of the products we use every day. |

From the perspective of a refrigerant supplier we understand how monotonous it is to complete handwritten hazardous waste notes every time you recover refrigerant into a cylinder. Paperwork can be time consuming – especially during busy periods at work.

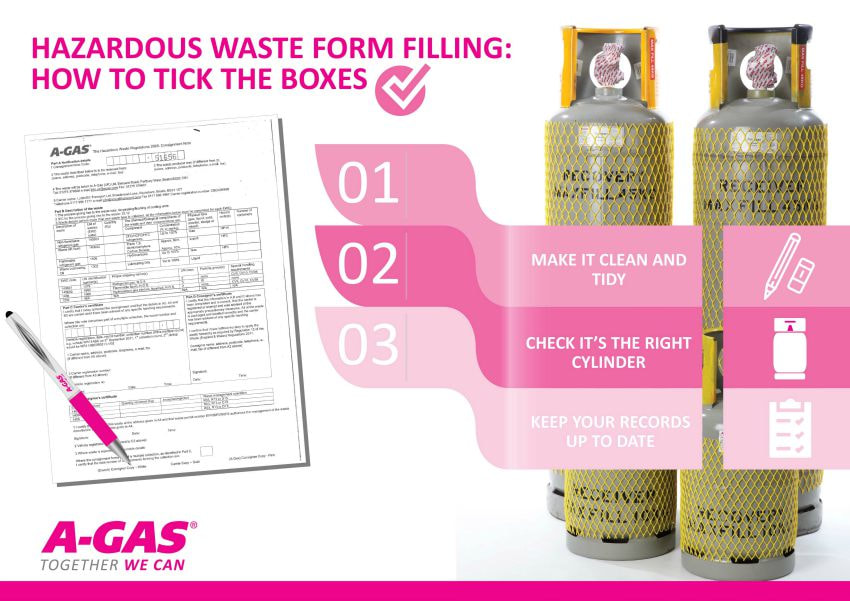

Hazardous waste notes must accompany all cylinders that contain recovered refrigerant through every step of the return process – from engineer handover to the wholesaler through to the wholesaler handover to A-Gas. As I am sure you can appreciate, with a handwritten form featuring at every stage of this returns’ process, by the time the paperwork reaches A-Gas it is sometimes difficult to read.

In the eyes of the law – and in a practical sense – it needs to be clean and legible and pass an on the spot inspection by the Environment Agency. So please take care and recognise the importance of this.

Chain of responsibility

These forms are part of the chain of responsibility which affects us all in the industry. They provide the written evidence that everything has been completed as it should. For the engineer, failure to complete these forms correctly can lead to a hefty fine or in the worst case imprisonment. These punishments range from a £300 on the spot fine to a two-year jail term.

There are strict rules regarding hazardous waste. If you are removing waste refrigerant from a refrigeration or air conditioning system you will need to hold the relevant qualification such as City & Guilds 2079. The regulations state that you may also require a waste carrier’s licence depending on the kind of waste you are carrying. This includes waste you as a contractor has recovered or waste you are carrying for others. This licence is issued by the Environment Agency and allows you to transport the refrigerant away from site.

The Hazardous Waste Regulations, and the ADR Regulations governing the transport of refrigerants, set out clear guidelines on this. With the Hazardous Waste Regulations contractors are given forms at the point of purchase – which in most cases is the wholesaler. The forms can also be downloaded from the Environment Agency website.

Typically, a contractor will take the recovery cylinder by van to the site where they are working, fill the cylinder with recovered refrigerant, then hand it back to the wholesaler.

Legal requirement

A-Gas will then collect the cylinder from its wholesale partner and take responsibility for the contents under their Waste Management Licence. But our drivers can be left with a problem if the cylinder numbers on the form don’t match up or the quantity of refrigerant is incorrect. Don’t forget that it’s a legal requirement to record the type and correct weight of gas.

The engineer, the wholesaler and A-Gas each receive copies of the waste disposal form. The end of the paper trail will result in A-Gas using its custom-built cylinder tracking, along with your hazardous waste notes, to report to the Environment Agency that the refrigerant waste it has received has been processed as it should be.

Using the correct cylinder is important. Receiver and recovery cylinders are not the same and have different purposes. Receiver cylinders are internally clean. This means they are the perfect option for those looking for temporary storage while they carry out routine maintenance or system repair.

Recovery cylinders on the other hand are to be used when you are looking to return recovered, unwanted refrigerant back to A-Gas for processing. We do not recommend recharging a system using refrigerant stored in a recovery cylinder as there is a risk that purity could be affected.

Recovered refrigerant

Regardless of the cylinder type you use, you must complete a hazardous waste note if you are returning recovered refrigerant to A-Gas. Remember, it is industry best practice not to mix products in cylinders – so use the right cylinder for the job to ensure that all safety measures are followed.

Contractors have a duty to act as a record keeper. Having received a response from the wholesaler on the fate of the refrigerant you returned – reclaimed or destroyed – you must maintain records of this for three years.

At times there does seem a lot to get your head around but help is on hand if you are unsure about the paperwork. A-Gas Rapid Recovery provides an outsourced refrigerant recovery service and will take care of all the form filling relating to the recovery of refrigerants which leaves you to get on with other key jobs on site.

Your wholesaler can also be very helpful. They can assist you on matters such as the premises code, consignment notes, descriptions of the waste, the Carrier’s Certificate and the Consignor’s Certificate. If you do get stuck don’t be afraid to ask them for help. Remember that for every recovery cylinder you buy you need to pick up a hazardous waste note and complete it in its entirety. It could save you a lot of heartache in the long run.

www.agas.com

Hazardous waste notes must accompany all cylinders that contain recovered refrigerant through every step of the return process – from engineer handover to the wholesaler through to the wholesaler handover to A-Gas. As I am sure you can appreciate, with a handwritten form featuring at every stage of this returns’ process, by the time the paperwork reaches A-Gas it is sometimes difficult to read.

In the eyes of the law – and in a practical sense – it needs to be clean and legible and pass an on the spot inspection by the Environment Agency. So please take care and recognise the importance of this.

Chain of responsibility

These forms are part of the chain of responsibility which affects us all in the industry. They provide the written evidence that everything has been completed as it should. For the engineer, failure to complete these forms correctly can lead to a hefty fine or in the worst case imprisonment. These punishments range from a £300 on the spot fine to a two-year jail term.

There are strict rules regarding hazardous waste. If you are removing waste refrigerant from a refrigeration or air conditioning system you will need to hold the relevant qualification such as City & Guilds 2079. The regulations state that you may also require a waste carrier’s licence depending on the kind of waste you are carrying. This includes waste you as a contractor has recovered or waste you are carrying for others. This licence is issued by the Environment Agency and allows you to transport the refrigerant away from site.

The Hazardous Waste Regulations, and the ADR Regulations governing the transport of refrigerants, set out clear guidelines on this. With the Hazardous Waste Regulations contractors are given forms at the point of purchase – which in most cases is the wholesaler. The forms can also be downloaded from the Environment Agency website.

Typically, a contractor will take the recovery cylinder by van to the site where they are working, fill the cylinder with recovered refrigerant, then hand it back to the wholesaler.

Legal requirement

A-Gas will then collect the cylinder from its wholesale partner and take responsibility for the contents under their Waste Management Licence. But our drivers can be left with a problem if the cylinder numbers on the form don’t match up or the quantity of refrigerant is incorrect. Don’t forget that it’s a legal requirement to record the type and correct weight of gas.

The engineer, the wholesaler and A-Gas each receive copies of the waste disposal form. The end of the paper trail will result in A-Gas using its custom-built cylinder tracking, along with your hazardous waste notes, to report to the Environment Agency that the refrigerant waste it has received has been processed as it should be.

Using the correct cylinder is important. Receiver and recovery cylinders are not the same and have different purposes. Receiver cylinders are internally clean. This means they are the perfect option for those looking for temporary storage while they carry out routine maintenance or system repair.

Recovery cylinders on the other hand are to be used when you are looking to return recovered, unwanted refrigerant back to A-Gas for processing. We do not recommend recharging a system using refrigerant stored in a recovery cylinder as there is a risk that purity could be affected.

Recovered refrigerant

Regardless of the cylinder type you use, you must complete a hazardous waste note if you are returning recovered refrigerant to A-Gas. Remember, it is industry best practice not to mix products in cylinders – so use the right cylinder for the job to ensure that all safety measures are followed.

Contractors have a duty to act as a record keeper. Having received a response from the wholesaler on the fate of the refrigerant you returned – reclaimed or destroyed – you must maintain records of this for three years.

At times there does seem a lot to get your head around but help is on hand if you are unsure about the paperwork. A-Gas Rapid Recovery provides an outsourced refrigerant recovery service and will take care of all the form filling relating to the recovery of refrigerants which leaves you to get on with other key jobs on site.

Your wholesaler can also be very helpful. They can assist you on matters such as the premises code, consignment notes, descriptions of the waste, the Carrier’s Certificate and the Consignor’s Certificate. If you do get stuck don’t be afraid to ask them for help. Remember that for every recovery cylinder you buy you need to pick up a hazardous waste note and complete it in its entirety. It could save you a lot of heartache in the long run.

www.agas.com

Content continues after advertisements