08 January 2025

|

Academics from around the world gathered for the Calorics 2024 conference at the Møller Institute, University of Cambridge, to discuss the latest advancements in solid-state technology for developing energy-efficient and eco-friendly heat transfer systems. ACR Journal editor Andy Slater discovered how different energy transfer methods might offer alternative cooling and heating products to those operating on vapour compression cycles.

Working within the refrigeration and air conditioning industry, we are sometimes blinded by the vapour compression cycle and obsessed with improving on topics like GWP and system efficiency. The United Nations’ Sustainable Development Goals recognise that decarbonising the heating and cooling sectors is paramount to tackling climate change. Governments and philanthropists, such as Bill Gates, founder of Breakthrough Energy, have offered support to discover new methods of providing cooling away from vapour compression, as global cooling demand is expected to triple in the next 30 years1 and energy generation is presenting its challenge as we try to move away from fossil fuel sources to renewable means.

Caloric materials are solid-state materials that undergo thermal changes when subjected to electrical or magnetic influences or stress changes. We unwittingly learn the foundations of electrocaloric, magnetocaloric, and electrocaloric processes while discovering physics and chemistry as children. Still, research by Hicham Johra of Aalborg University shows that scientific papers referencing caloric effects and systems have risen dramatically from the year 2000 after sporadic appearances in the late 1940s to mid-1950s, demonstrating that solid-state refrigerants are gaining considerable attention2.

Elastocaloric effect

Materials subject to mechanical stresses such as uniaxial expansion or contraction can transfer energy to their surroundings to generate a cooling or heating effect. This thermodynamic change results from the realignment of the material’s crystalline structure and changes in entropy. If the material is compressed, it rejects heat, and when it is stretched, it absorbs heat.

Shape memory alloys (SMA) are typically used as elastocaloric materials, such as copper-zinc-aluminium alloys, but rubber can also be used. The amount of temperature change depends on several material characteristics, such as its microstructure and composition, in addition to the mechanical force exerted on it. Its ability to resist retardation from repeated application of force is critical, and a lot of alloy-based materials require a sleeve to surround the material to maintain form.

Electrocaloric effect

A dielectric material where the electric current doesn’t flow freely (electrical insulator) can exhibit temperature changes when an electric field is passed through it. The dipoles, molecules with positive and negative poles, align and release heat due to decreased entropy as the electrical field is applied. When the electrical field is removed, the dipoles revert to a disordered state and absorb energy from their surroundings, providing a cooling effect.

Magnetocaloric effect

When a magnetocaloric material is subjected to a magnetic force, its magnetic domains (a microscopic region within the material atoms affected by a magnetic field) align, reducing entropy and resulting in heat loss from the material itself if the heat is radiated away. When the magnetic field is removed, if the material cannot absorb energy from its surroundings, its magnetic domains absorb thermal energy from the material itself, and the magnetocaloric material cools to below its original temperature.

Energy recovery

Most effective cooling and heating processes are energy intensive and typically consume electricity, whether to drive mechanical components such as a compressor, generate mechanical action to stretch material, provide electrical current, or generate a magnetic field. Energy recovery is essential to maximising the efficiency of all processes, even solid-state cooling.

Considering that every action in solid-state processes has an opposite reaction, it is sensible to take advantage of each process's cooling and heating effects to increase system efficiency and improve viability. This typically involves cooling and heating two different water circuits from one mechanical process.

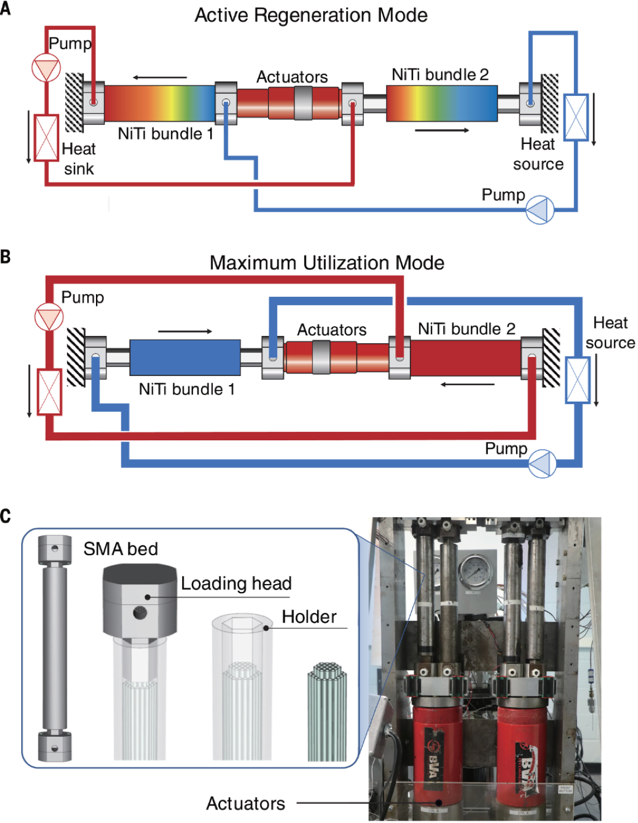

Figure 1, above, is an extract from an article3 placed in Science.org. It shows the system design and operating principles of a multimode electrocaloric cooling system, which provided 260 watts of cooling power and a maximum temperature span of 22.5 kelvin. It is an example of how solid-state technology can be scaled, with this example adopting a physical size of 1300 x 800mm. It uses fatigue-resistant elastocaloric nitinol (NiTi) tubes configured in a multimode configuration, meaning heating and cooling can occur simultaneously with mechanical forces when compressing and unloading, complementing each other to increase system efficiency.

Application

Discovering suitable caloric materials is just the beginning of the development of solid-state cooling technologies. The next challenge is developing scalable processes to transfer the technology into suitable applications. Caloric heat pump systems already exist; and have done since the 1980s4 . They are an immature technology with a lot of potential, barriers such as cheaper magnetoalroc material and component optimisation are currently preventing a competitive market to traditional vapour compression systems.

Baracol, a solid-state technology research and developer, demonstrated its prototype bottle cooler after the conference. The cooler, which results from over 15 years of research at the University of Cambridge, is a quiet, zero-global warming potential cooling system that provides chilled refreshments with efficiencies reportedly two to three times higher than conventional methods.

Sources:

1 IEA: The future of cooling 2018

2 Performance overview of caloric heat pumps: magnetocaloric, elastocaloric, electrocaloric and barocaloric systems: Update 2024

3 https://www.science.org/doi/10.1126/science.adg7043

4 https://www.rehva.eu/rehva-journal/chapter/magnetocaloric-heat-pumps-innovative-heating-and-cooling-systems-1

Further Reading: