03 November 2017

|

|

Conex Bänninger believes its latest press-fit system is about to signal significant changes in the UK air conditioning and refrigeration market.

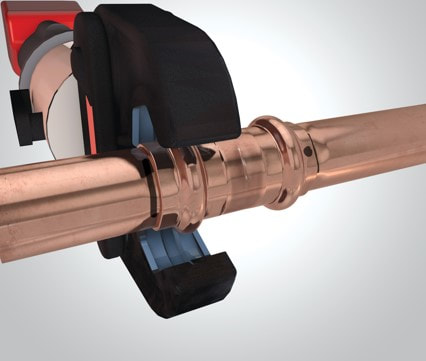

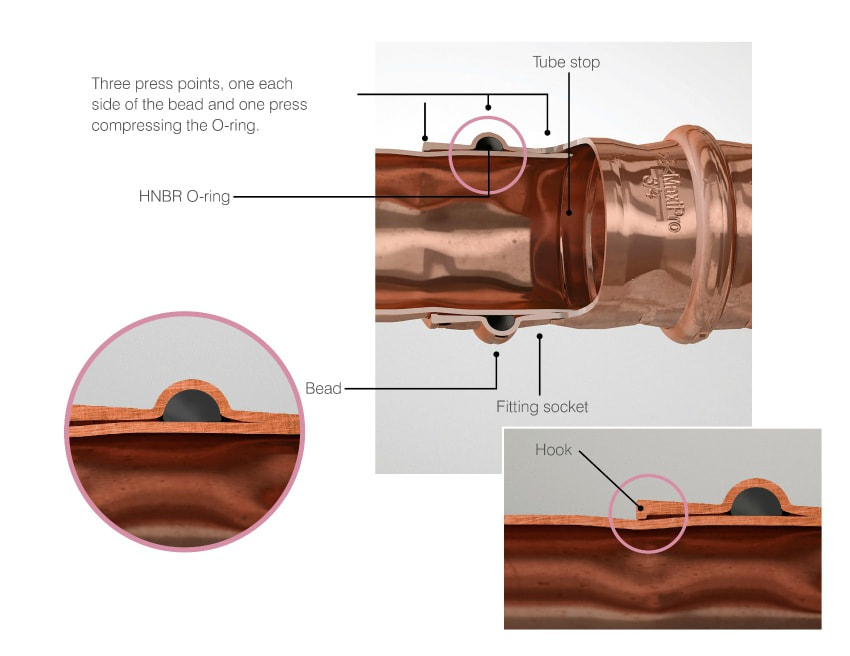

The copper >B< MaxiPro uses Conex Bänninger’s three-point-press technology, where three presses are made, one each side of the bead and one compressing the O-ring. It has been designed for use in systems with operating pressures of up to 48 bar. |

|

|

The flame-free solution means there is no requirement for hot work permits and, as a mechanical joint, there is no need for a nitrogen purge during jointing.

Mano Bakhtiari, CEO of Conex Bänninger parent company, IBP Group, introduced the product at the official UK launch in London and said: “It is a cleaner, easier, faster safer and more reliable way to work. We are not trying to de-skill the role of engineers; this is an opportunity to lead the industry into new techniques.’’ Innovative Although Bakhtiari believes a full conversion from traditional brazing methods could take “60-70 years”, he said he would like to see press-fit acounting for 50 per cent of the installation market in five years. The system was devised in 2012 and has since been developed and extensively tested before its introduction to the Australian, US and now UK markets. Bill Barlow, Business Unit Director, UK – OEM & ACR at Conex Bänninger, added: “With the success of Conex Bänninger’s >B< MaxiPro launch in other international markets, we firmly believe that we have developed an innovative product that provides a best-in-class solution for UK contractors and engineers in air conditioning and refrigeration applications. “As a revolutionary press-fit product, we are confident that >B< MaxiPro will further establish IBP Group’s UK ACR market presence, ensuring that Conex Bänninger is seen as the trusted brand in the industry, consistently delivering product excellence and value to our customers and end users.” The product is available in a host of fittings types including, Straight Coupler, Reducing Coupler, Fitting Reducer, 90o Bend, 90o Street Bend, 45o Obtuse Elbow, Equal Tee and Stop End variants. Bill Barlow, Business Unit Director, UK – OEM & ACR at Conex Bänninger, said: “With the success of Conex Bänninger’s >B< MaxiPro launch in other international markets, we firmly believe that we have developed an innovative product that provides a best-in-class solution for UK contractors and engineers in air-conditioning and refrigeration applications. Training “As a revolutionary press-fit product, we are confident that >B< MaxiPro will further establish IBP Group’s UK ACR market presence, ensuring that Conex Bänninger seen as the trusted brand in the industry, consistently delivering product excellence and value to our customers and end users.” >B< MaxiPro fittings can be used with annealed, half hard or hard copper tube that conforms to EN 12735-1 or ASTM-B280 in air-conditioning and refrigeration applications. They are available from Dean & Wood, HRP, RW, Climate Center, Brymec and Alpha Wholesale. They are also approved for use with a range of refrigerants, including R-32, R-134a, R-404A, R-407C, R-407F, R-410A, R-507, R1234ze, R1234yf, R-718, R-450A, R-513A, R-448A, R-449A, R-407A, R-427A, R-438A, R-417A and R-422D. Conex Bänninger recommends the use of Rothenberger’s lightweight press tools and jaws for installations. The Romax Compact Model uses Constant Force Technology and the jaws are good for 20,000 press cycles.. >B< MaxiPro carries a certified training course and when professionally installed and used in accordance with these guidelines, the guarantee is increased to 5 years against manufacturing defects. www.conexbanninger.com |

Content continues after advertisements